ISO JIS Z 2801 (2010)

Measurement for Antiviral Activity and Efficacy (Japanese Standard)

Tested:

Influenza A Virus – H1N1

ISO 21702

Measurement of antiviral activity on absorbent & non-absorbent surfaces

Tested:

SARS-CoV-2

Feline Corona Virus

ISO 18184:2019

Determination of antiviral activity in textile products

Tested:

Feline Corona Virus, Strain Munich

BS EN 1276:2019

Quantitative suspension test for the evaluation of the bactericidal activity of chemical disinfectants and antiseptics

Tested:

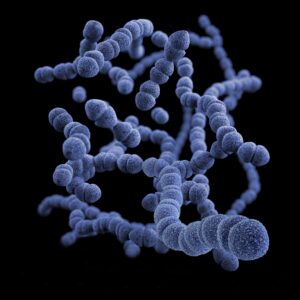

Staphylococcus aureus

Escherichia Coli

Pseudomonas Aeruginosa

Enterococcus Hirae

EN 1040:2005

Quantitative suspension test for the evaluation of basic bactericidal activity of chemical disinfectants and antiseptics

Tested:

Staphylococcus aureus

Escherichia Coli

Pseudomonas Aeruginosa

Enterococcus Hirae

ISO 20743:2013

Determination of antibacterial activity in textile products

Tested:

Staphylococcus aureus

Escherichia Coli

Klebsiella Pneumoniae

ISO 22196

Certification of duration and effectiveness: 12 months

Measurement of Antibacterial Activity on Plastic Surfaces (British Standard)

Tested:

Staphylococcus aureus

Escherichia Coli

SANS 51276 (EN2176)

Evaluation of Bactericidal activity of Chemical Disinfectants used in Food companies, Industry, Domestic & Professional areas

Tested:

Staphylococcus aureus

Escherichia coli

Pseudomonas Aeruginosa

Candida albicans

Aspergillus brasiliensis

EN45545-2 HL3

European Union Standard for Fire Testing of Materials and Components

ISO JIS Z 2801 (2010)

Measurement for Antiviral Activity and Efficacy (Japanese Standard)

Tested:

Influenza A Virus – H1N1

JIS Z 2801 method is a quantitative test method for determining the antimicrobial efficacy and overall activity of disinfectant products on non-absorbent surfaces made of plastic, metals, glass, ceramic, rubber, silicone, glass, lacquers and other similar materials as well as polymer-coated surfaces. The test excludes all textile products and surfaces resulted from photocatalysis.

After 7 days, iQx coated surfaces showed 99.9% virus reduction.

Accordingly, even after 30 days, its activity against the virus continued without showing any decreasing activity or efficiency, also amounted to >99.9%.

ISO 21702

Measurement of antiviral activity on absorbent & non-absorbent surfaces

Tested:

SARS-CoV-2

Feline Corona Virus

ISO 21702 is a measurement of microbial load on surfaces by testing the antiviral activity of the disinfectant on plastic, glass and other non-porous surfaces.

With the current coronavirus outbreak, this is a more important test for the effectiveness of the i iQx coating.

This standard is used to certify the antiviral activity of iQx against viruses, including the SARS-CoV-2 virus.

The test was performed in laboratory by contact with the virus for 24 hours. iQx performed most efficiently and it was >99% active within 20 minutes

ISO 18184:2019

Determination of antiviral activity in textile products

Tested:

FELINE CORONA VIRUS, Strain Munich

This measurement specifies test methods for determining the antiviral activity of the antimicrobial species in textiles against specified viruses.

Due to individual sensitivities, the results of a test virus cannot be transferred to other virus types. iQx in this method is tested for its effectiveness against the coronavirus.

Textile products include woven and knitted fabrics, fibers, yarns, etc.

iQx delivered over 95% antimicrobial activity within 20 minutes.

This means that the sample showed 95% less pathogens than those recorded in the control group.

BS EN 1276:2019

Quantitative suspension test for the evaluation of the bactericidal activity of chemical disinfectants and antiseptics

Tested:

Staphylococcus aureus

Escherichia Coli

Pseudomonas Aeruginosa

Enterococcus Hirae

This European Certification defines a test method and Standards for the bactericidal activity of chemical disinfectants and antiseptic products which form a homogeneous, physically stable formulation when diluted with water or – in the case of ready to use products – with water.

Products can only be tested at a concentration of 80% or less, as some dilution is always produced by the addition of the test microbes.

This certification applies to products used in food processing, industrial, domestic and institutional areas, excluding areas and situations where disinfection is medically indicated and excludes products used on living tissue, except for hand hygiene in the areas covered above.

iQx showed at least 99.99% efficiency within the first 5 minutes.

EN 1040:2005

Quantitative suspension test for the evaluation of basic bactericidal activity of chemical disinfectants and antiseptics

Tested:

Staphylococcus aureus

Escherichia Coli

Pseudomonas aeruginosa

EN 1040 is a phase 1 suspension test for the evaluation of basic bactericidal activity in chemical disinfectants.

For iQx we used this standard in the product development process and in the verification of antimicrobial activity on a range of surfaces. The test is applied to active substances (antibacterial biocides) and preparations under development planned for use in food, industrial, domestic, public, medical and veterinary areas.

iQx performed efficiently over 99.99% in most cases throughout the test run.

DERMATEST

Accredited test procedure to assess skin compatibility (Tested on humans)

One of the most basic tests of our product has been conducted to determine its safety on your skin.

Patch tests are used to investigate whether products or substances cause primary skin irritation.

In addition, they are also able to identify any existing sensitivities. If an irritation reaction is detected, this indicates that the test substance causes primary irritation.

We did these tests to make sure that if a customer comes into contact with the liquid or coating there will be no skin irritation.

iQx coating is thoroughly tested under standardised conditions, while simulating as much as possible the actual conditions of use.

We tested the skin contact with iQx on human skin over a much longer contact time than you would have in a realistic situation in order to avoid any unpleasant surprises.

The tests have been conducted on various skin types in men and women.

ISO 20743:2013

Determination of antibacterial activity on textile products

Tested:

Staphylococcus aureus

Escherichia Coli

Klebsiella Pneumoniae

This ISO Standard specifies quantitative test methods for determining the antibacterial activity of all fabrics, including non-woven and can be used for corresponding product registrations.

ISO 20743:2013 applies to all textile products, including fabrics, wadding, yarns and materials for clothing, bedding, home furnishings and sundries, regardless of the type of antibacterial agent used (organic, inorganic, natural or synthetic) in in our case the fabric treatment or the way of application (embedded, secondary treatment or placement in the final product).

Based on the anticipated application and setting in which the textile product will be used, as well as the surface properties of the fabric, the user can choose the most appropriate of the following three inoculation methods to determine antibacterial activity:

a) absorption method (assessment method in which the bacterial suspension is tested and placed directly on samples).

b) transfer method (assessment method in which the test bacteria are placed on an agar plate and transferred to samples).

c) printing method (assessment method in which test bacteria are placed on a filter and printed on samples).

The colony plate count method and the ATP (ATP = Adenosine Triphosphate) luminescence method are also established to measure bacterial enumeration.

ISO 22196

Certification of duration and effectiveness: 12 months

Measurement of Antibacterial Activity on Plastic Surfaces (British Standard)

Tested:

Staphylococcus aureus

Escherichia Coli

ISO 22196:2007 specifies a method for determining the activity of antibacterial / antimicrobial products on plastic surfaces.

In this test, the coating has been tested through a laboratory aging process to certify the activity and effectiveness of the product after 12 months.

It is not intended to be used to evaluate the effects and spread of bacteria on plastics without antibacterial treatments.

ISO 22196 TEST SUMMARY

- Test microbes are prepared, usually by growth in a liquid culture medium. According to the method, two representative microbes are identified, S.aureus and E.coli which are widely used by many laboratories internationally.

- The test microorganism suspension is standardized by dilution in a nutrient solution that allows the bacteria to grow during the test.

- Control and test surfaces are inoculated with microorganisms and then the microbial inoculum is covered with a thin, sterile coating.

- Testing is performed to verify that the neutralization / release method effectively neutralizes the antimicrobial agent on the antimicrobial surface being tested.

- All samples and the control group are incubated and kept undisturbed in a moist environment for 24 hours.

- After incubation, microbial concentrations are determined. The reduction of microorganisms in relation to the initial concentrations and the control surface is calculated.

After laboratory testing, iQx showed a completely satisfactory antibacterial activity of >99.99% for a period of at least 12 months.

SANS 51276 (EN2176)

Evaluation of Bactericidal activity of Chemical Disinfectants used in Food companies, Industry, Domestic & Professional areas

Tested:

Staphylococcus aureus

Escherichia coli

Pseudomonas Aeruginosa

Candida albicans

Aspergillus brasiliensis

This certification applies a standard for antibacterial disinfection products.

These standards are equivalent to a South African international standard that standardizes the efficacy of chemical disinfectants and is used by the hospitality industry and food preparation installations.

To qualify for this standard, a disinfectant must effectively kill 99.999% of bacteria within 5 minutes of use.

This was demonstrated by the iQx during the laboratory test based on the specific Standard

ISO- 5660-1

Reaction of the product to fire tests – Heat release, smoke production & mass loss rate

When testing a product according to ISO 5660, a specimen with a dimension of 100 mm x 100 mm is used for testing. The surface of the sample is heated and begins to emit gases that are ignited by a spark igniter. The emitted gases are collected in a hood and carried away through a ventilation system.

Heat release is measured using data on the measurable oxygen concentration in the emitted smoke. Smoke production is continuously measured throughout the test with a laser system.

The iQx passed this test with flying colours as well.

EN45545-2 HL3

European Union Standard for Fire Testing of Materials and Components

This European railway fire safety standard was introduced as a mandatory requirement across Europe. Today, all materials used in the construction of railway vehicles must follow this standard to achieve the highest possible level of safety in the event of a fire.

It aims to protect passengers and staff from fire incidents on board railway vehicles. It applies to all manufacturers of rail vehicles including high-speed trains, regional trains, trams, metros and double-decker trains.

Having passed the tests, our anti-viral coating has been approved according to EN 45545-2 for use on trains. This test has been prepared in cooperation with the company Kiel Seatings, the largest manufacturer of train seats in Europe.

Key parameters measured include flame spread, ignition, heat release, smoke opacity and toxicity.

EN45545-2 sets more stringent testing as a standard requirement for the fire behaviour of materials and components including floors, seats and cables in railway vehicles. Our product iQx also falls under this requirement. The test specifies the research, test methods, test conditions and fire reaction performance requirements. Our antimicrobial coating is classified according to 26 sets of requirements (R1-R26). Each requirement has a corresponding set of test performance criteria.

Risk levels

Railway vehicles are classified according to the level of fire risk associated with their design and operation. There are three levels of risk. HL1, HL2 and HL3 with HL1 being the lowest requirement and HL3 being the highest. iQx has reached the highest levels in HL3.

Tests

A series of tests were performed on the coating to measure how the iQx coating would compare to the set of product requirements. Some testing methods include:

- TO1 Oxygen Index

- 03 Exhaust gas density

- T12 Smoke toxicity